Fire Season

If you’ve been watching or reading the news, chances are you have heard about the possible power outages coming as a result of fire danger this summer. The big three utility companies (PG&E, SCE, and SDG&E) have all announced that they will be shutting off utility power under certain conditions as part of the CPUC’s (California Public Utilities Commission) new Public Safety Power Shutoff Program. This program is in full effect as of July 1st which is the start of fire season.

Some of the factors being considered prior to a shut down:

- National Weather Service Red Flag Warning

- Low Humidity Levels

- Forecasted sustained winds generally above 25mph and wind gusts in excess of approx. 45mph

- Condition of dry fuel on the ground and live vegetation

- On-the-ground, real-time observations

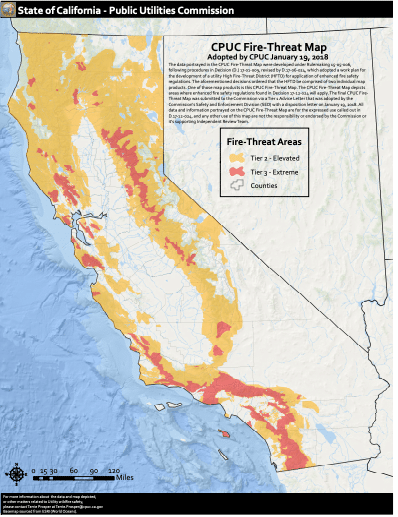

Know your area’s fire threat

The utility companies will try to give a 24-48 hour notice if possible, but as conditions like the ones mentioned above can change rapidly, there is no guarantee. You can view your area’s fire risk assessment on the map here:

Here’s what PG&E has to say in their press release…

“While customers in high fire-threat areas are more likely to be affected, any of PG&E’s more than 5 million electric customers could have their power shut off if their community relies upon a line that passes through a high fire-threat area.”

What can you do to prepare?

If you have a back-up power system in place, whether it is a UPS, Inverter, or Generator: Have you taken a recent look at what critical load it supports? Do you have enough back-up power to keep your business operational and not lose critical revenue to outage-related downtime? When was the last time a full maintenance service was performed? If you are unsure or it’s been more than a few months, we would highly encourage you to schedule a full service to check critical components which are at highest risk of failure, particularly batteries, fans, and capacitors on a UPS and oil, filters, and cooling/fuel systems on your generator.

For your UPS System, if you have been holding off on a battery replacement or other repair, now is the time to move forward with it. The last thing you want to be waiting on in the event of an outage is out of stock batteries, which could take weeks to get in. Also, we encourage you to know the battery runtime of your unit based on current load readings. If your unit is too heavily loaded, it could trip into bypass or offline. When an outage does occur, know your runtime so that as the clock is ticking you can be prepared to shut down the load before the batteries are drained.

For your Generator, now would be a great time to check the fuel level and arrange for a top-off to ensure maximum runtime before needing a refill. In addition, if it has been more than 10 months since your last oil and filter change, you may want to consider having this service performed to ensure your unit is in the best possible shape to sustain a long outage. Has it been a few years since you have had your coolant tested or replaced or a load bank performed? These services can help assess the condition of your unit prior to an outage.

Lastly, we recommend exercising your ATS (automatic transfer switch) in order to check for proper operation. If the mechanism is sticking, you can perform a de-energized service to clean, lubricate, and recalibrate the switch. The ATS is the main sensing device which ensures that the transition from utility to back-up power happens seamlessly. If the ATS does not operate correctly, your entire back-up power system will not come online.

We just had an outage and our power is out. What can we do?

You have a few options, but we are already seeing that the fleet of portable rental generators is getting depleted by companies placing them under long-term lease for fire season. If you are looking at this as a possible solution, Odyssey can help. However, with the threat of shutdowns looming on the horizon, there may not be a high level of availability. Your best bet is to have a system in place BEFORE a shut down occurs in order to minimize any disruption to your business operation and revenue.

Not sure where to start?

Odyssey Power can help. With our experienced technicians, we can perform a full evaluation and maintenance service on your critical power equipment components. Whether Inverter, Generator, or UPS, we are uniquely able to assist with your entire back-up power infrastructure. As the only company with both UPS and Generator technicians on staff, we are able to look through your entire system to ensure that not only do the individual components function but that they all communicate and work together to keep your critical infrastructure online.

Maximizing your business uptime is what we do on a daily basis and fire season is no different. Let Odyssey’s team work with you to prepare the best solution for your business. Contact us today to get started.